德马吉森精机LASERTEC 65 3D在5轴数控加工中心上开发组合激光沉积焊接的AM(增材制造)功能。适合加工的金属粉体材料包括不锈钢、难切削材料因康镍合金(镍基合金的一种)等。

德马吉森精机的5轴加工中心LASERTEC 65 AdditiveManufacturing具有激光沉积焊接的增材制造功能,, 是现有的数控切削加工和“增材制造(Additive Manufacturing, AM)”功能加以组合的混合型设备方案。新设备使用独特的粉末喷嘴,相比以往的金属粉末积层法最大可实现20倍的积层速度。

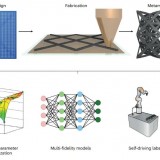

增材制造设备适用于飞机零部件和医疗设备零部件相关的复杂工件(加工对象物)制造与修理。激光沉积焊接采用2千瓦二极管激光,数控铣削加工和激光加工可完全自动切换,金属粉末由激光凝固完成积层,再进行数控切削加工。每小时的制造效率最大为3.5千克,料厚对应0.1mm-5mm。相当于传统数控加工和3D打印增材制造的结合,用增材制造的方法在一台机床上把形状“堆积”起来,再用数控加工的方法进行轻切,把多余的不符合精度要求的物料切除。

录像链接》

LASERTEC 65 3D

ALL IN 1: Laser Deposition Welding & Milling -additive Manufacturing in Milling quality

DMG MORI integrates for the first time the additive manufacturing into a high-tech 5-axis milling machine. This innovative hybrid-solution combines the flexibility of the laser metal deposition process with the precision of the cutting process and therewith allows additive manufacturing in milling quality.

The process uses the metal deposition by powder nozzle, which is up to 10-times faster than the generation in the powder bed.

Up to now additive technologies have been used to generate prototypes and small parts. By combining both, additive manufacturing via powder nozzle and the traditional cutting method in one machine, totally new applications and geometries are possible. Especially large workpieces with high stock removal volumes are now possible to be machined in an economical way. The flexible change between laser and milling operation allows the direct milling machining of sections which are not reachable anymore at the finished part.

3D科学谷编译自:www.dmgmori.com,欢迎转载并链接www.51chape.com